State-of-the-art

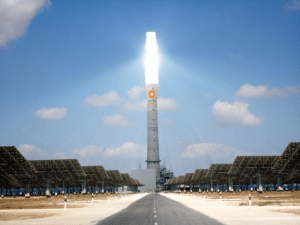

One way of producing electricity from the energy of sunlight is to concentrate the solar energy on a focal point by means of movable mirrors that track the sun, providing high-temperature heat. The high-quality thermal energy obtained in this way is converted efficiently into electrical power. For this purpose, a heat exchanger (receiver) is used, located in the concentration field of the radiation, in which a heat transfer fluid (HTF) is first solar-heated and then utilised to generate steam further used in the operation of a conventional power cycle to produce electricity. Such solar tower power plants have an inherent straightforward way to store solar energy since the generated heat is easier storable than electricity and can thus be used for later conversion to electric power. Combined with thermal energy storage (TES) of several hours of full-capacity generation, concentrated solar power (CSP) plants can continue to produce electricity even when clouds block the sun, after sundown or in early morning when power demand steps up. This is matched by the current trend of building solar power towers with molten salts as heat transfer and storage medium like e.g. in the 20 MWel Gemasolar plant in Fuentes de Andalucía, Spain or the 110 MWel solar tower of the Crescent Dunes project in Nevada, USA, both shown in Figure 1.

Figure 1: Photos of commercial solar power tower

(Photo by Greg Glatzmaier, NREL 19807)

(Photo by Dennis Schroeder, NREL 46180)

However, this current baseline storage technology for CSP power towers using molten salts as a sensible heat storage medium implies the following drawbacks:

- Maximum operating temperature of molten salt is around 550 °C which limits the potential process efficiency.

- Heat tracing is required in molten salt storage systems to keep the salt from freezing during routine maintenance and unplanned events.

- The storage medium must be kept at an elevated temperature for the system to function.

- Molten salt storage is not suitable for long term (>48 hours) application as heat stored in the medium will inevitably be lost to the environment. For this reason, it cannot be used for seasonal storage.

Concept

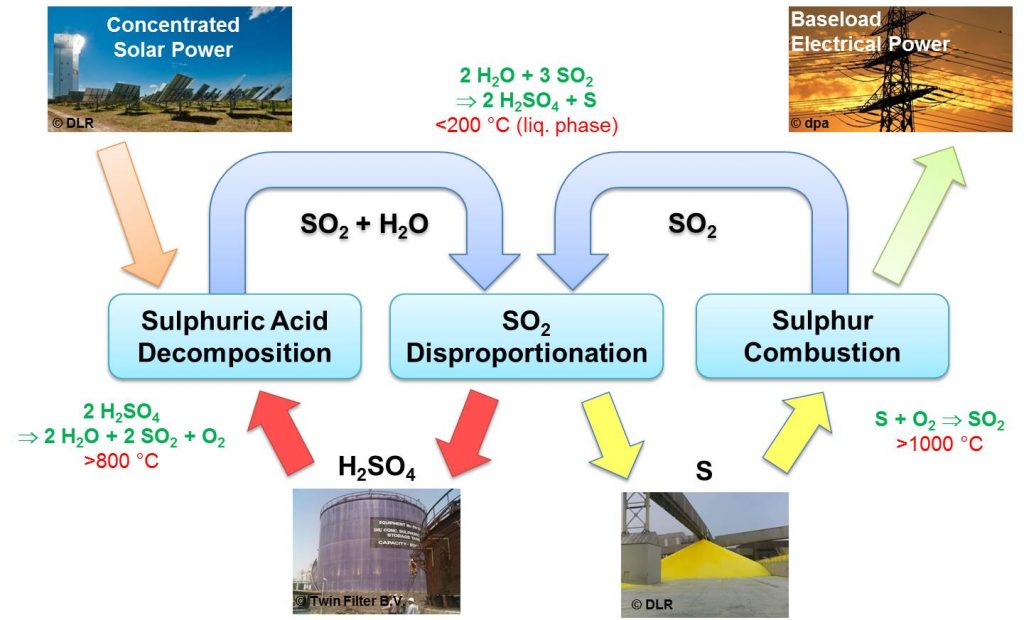

In order to overcome the drawbacks of state-of-the art molten solar power tower technology a thermochemical cycle is introduced to convert solar heat into chemical energy storing, thus, solar in the chemical bonds of the storage medium leading to very higher storage densities without heat losses. Sulphur represents a prime candidate of a storage material, which can be generated by a thermochemical storage cycle comprised of the sequence of chemical reactions described schematically in Figure 2. In the first reaction, high-temperature heat from a CSP plant is used to decompose sulphuric acid (H2SO4) into water (H2O), sulphur dioxide (SO2) and oxygen (O2). In the second step, the decomposed SO2 gas is used to support a disproportionation reaction to produce elemental sulphur (S) and H2SO4 (cf. Wong et al. (2015) Sol Energ). This sulphur can then be combusted in air to produce high-temperature heat and SO2 in the third step. The SO2 from combustion can be converted back into sulphur and H2SO4 in a conventional sulphuric acid plant. Sulphur combustion can produce high quality heat at temperatures in excess of 1200 °C, suitable for electricity generation using a gas turbine.

Figure 2:

There are a number of advantages in using sulphur to store solar energy:

- Extremely high storage density: sulphur is one of the lightest solid elements. The storage capacity of sulphur is more than an order of magnitude higher than sensible heat storage based on molten salt. As an example, a 50 MWe plant with 15 hours of molten salt storage will require a daily salt inventory of 70,500 metric tons (t) while the same size plant based on a sulphur thermochemical cycle will require only 1,500 t of sulphur and 4,800 t of sulphuric acid.

- Sulphur is a very cost-effective material (< 200 €/t).

- Sulphur can be cheaply stored for very long times and in huge amounts just on a pile outdoor under ambient conditions or in liquid form at ~140 °C in a tank.

- Heat is recovered at a constant temperature which is preferred for turbine operation.

- In contrast to other known heat storage mechanisms, the stored energy can be retrieved at a temperature higher than that of the original heat input.

Figure 3: Storage of sulphur on a bulk handling installation in Brake, Germany

of ∅ 3…6 mm on a pile

∅ 3…6 mm inside a silo of 30,000 t

of 40,000 t

Methodology

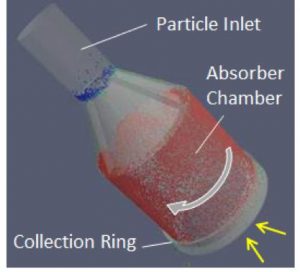

PEGASUS introduces a novel centrifugal particle receiver developed by DLR in order to capture solar radiation. The receiver consists of a fast rotating cylindrical cavity (Figure 4), where particles of about 1 mm diameter (Figure 5) are introduced at the upper double-walled cone on the rotational axis. Radial ribs accelerate the particles to the rotational speed of the receiver. A thin but optically dense particle film is established by centrifugal forces on the inner surface of the rotating cylindrical absorber chamber. The particles move along the cylindrical wall towards the outlet at the lower end. While the particles move downwards, they absorb the concentrated solar radiation which enters the receiver through the bottom aperture and are gradually heated. An insulated collection ring at the particle outlet collects the hot particles for transportation to the storage module. Depending on the incoming heat flux, the particle residence time can be adjusted by controlling rotation speed and mass flow rate. A unique feature is the adjustment of particle velocity by simply controlling the speed of rotation. With the controlled particle retention time, the outlet temperature can be easily adjusted to the desired value. This is an important advantage compared to direct absorbing falling particle receivers, where the falling speed of the particles can hardly be controlled.

Figure 4 and Figure 5:

A video of the centrifugal particle receiver technology:

A small prototype (15 kWth) of the centrifugal receiver concept was successfully tested at DLR high flux test lab reaching 900 °C particle outlet temperature and 80 % receiver efficiency. In a next step, this concept was scaled up to a prototype of power level of 2.5 MWth including a complete particle transport system and installed at the Juelich Solar Power Tower (Press release by DLR on 23rd May 2017).

Objectives

The overall objective of PEGASUS is the development and demonstration of an innovative solar tower system based on solid particles combined with a novel thermochemical solar energy storage technology based on elemental sulphur, to achieve dispatchable and firm renewable electricity generation with a significant cost reduction with respect to current state-of-the-art concepts. The technology will be validated under real on-sun concentrated solar irradiation in the Juelich Solar Power Tower thermal plant in Germany owned by the project coordinator, DLR. In this perspective, the project’s specific technical objectives are:

- Combine and further improve current state-of-the-art proppant properties and SO3-splitting catalysts (e.g. Karagiannakis et al. (2012) Int J Hydrogen Energ) in synthesizing catalytically active particles that can demonstrate in combination:

- conversion of SO3 to SO2 and O2 close to the respective thermodynamic value

- low deactivation of initial catalytic activity in the course of long-term exposure to reaction conditions

- high solar absorptivity during lifetime

- cost of losses due to abrasion or chemical inactivity.

- Synthesize the necessary large-scale quantities (>3 tons) of such particles and demonstrate on-sun the capability of a prototype 500 kWth centrifugal particle solar receiver for heating such particle streams to temperatures in excess of 900 °C.

- Design a high-temperature particle storage system that can maintain particle temperatures higher than 900 °C for at least 6 hours.

- Design, build and operate a laboratory prototype sulphuric acid decomposition cascade consisting of a sulphuric acid evaporator and an SO3 decomposer heat exchanger, employing moving heated particles as the heat source required for both these processes.

- Develop and realize a novel lab-scale sulphur burner in the 10 kW range able to modulate up to 15 bar outlet pressure for gas turbine application.

- Demonstrate the feasibility of the over-all process, draft the complete flowsheet and techno-economic analysis of optimized integrated process scaled-up to the 5 MWth power level, assess the technology vs. the targets set and evaluate its potential with respect of realizing a sulphur storage cycle enabling solar power production at levelized electricity costs (LCOE) of 0.08 €/kWh.